Micro-Precision and Micro-Miniature Stamping Excellence

Ditron, Inc. delivers ultra-precise micro stamped metal components that power today’s most advanced technologies—where failure is not an option.

Visit PrecisionX Group at Booth 3710!

Join us at MD&M West in Anaheim, CA, February 4-6, 2025. Discover precision solutions for critical industries!

Core Capabilities

Our micro stamping capabilities allow us to produce extremely small, intricate components with tight tolerances, perfect for medical devices and electronics that demand high precision.

The PrecisionX Group offers a robust portfolio, including deep drawing, progressive stamping, CNC machining, Swiss machining, laser marking, laser welding, and more. With expansive facilities and expertise across multiple industries, we provide solutions for your complex manufacturing needs. Brands include: GEM, Coining, National Manufacturing, Ditron, MSK Precision Productts.

Industries & Applications Served

In aerospace and defense, materials that perform reliably in harsh environments are essential. We specialize in high-performance metals like Inconel, Titanium, and Hastelloy, engineered to withstand extreme conditions. Our expertise ensures your parts meet strict industry standards for mission-critical success in even the toughest environments.

Precision is the foundation of success in the medical device industry. We manufacture your high-reliability components to meet stringent regulatory standards, ensuring accuracy, durability, and performance in life-saving devices. Our expertise in deep draw technologies and tight tolerances enables us to support the development of innovative medical solutions.

By partnering closely with our customers, we manufacture critical components that meet the extreme demands of space applications. Precision-engineered parts are essential to the performance and reliability of satellite and telecommunications systems, supporting communication, navigation, and data collection missions.

As the need for innovation accelerates, we partner with our customers’ engineering teams to manufacture the critical components that power the next generation of EVs. From precision metal parts to advanced manufacturing solutions, we deliver excellence.

In the mining industry, precision and reliability are essential. Blasting caps and other critical components are crafted to perform in the harshest environments. By partnering with your engineers, we deliver durable, high-quality solutions that ensure efficiency.

Our advanced capabilities in metal forming, stamping, and machining ensure the highest quality parts for critical PCB applications. Whether it’s connectors, shields, or custom components, we manufacture to exacting specifications, providing reliable and durable solutions that enhance PCB performance.

About Us

Micro-Miniature Metal Stamping with Mega Precision and Service

Founded in 1963, Ditron, Inc. has built a global reputation for excellence in micro miniature metal stamping—producing ultra-small, tight-tolerance components that power mission-critical applications in electronics, aerospace, medical, automotive, and telecommunications.

In 2025, Ditron proudly joined PrecisionX Group, expanding our capabilities and customer reach while continuing to deliver the unmatched service and quality that has defined us for over six decades.

A Legacy of Innovation in Small-Form Metal Stamping

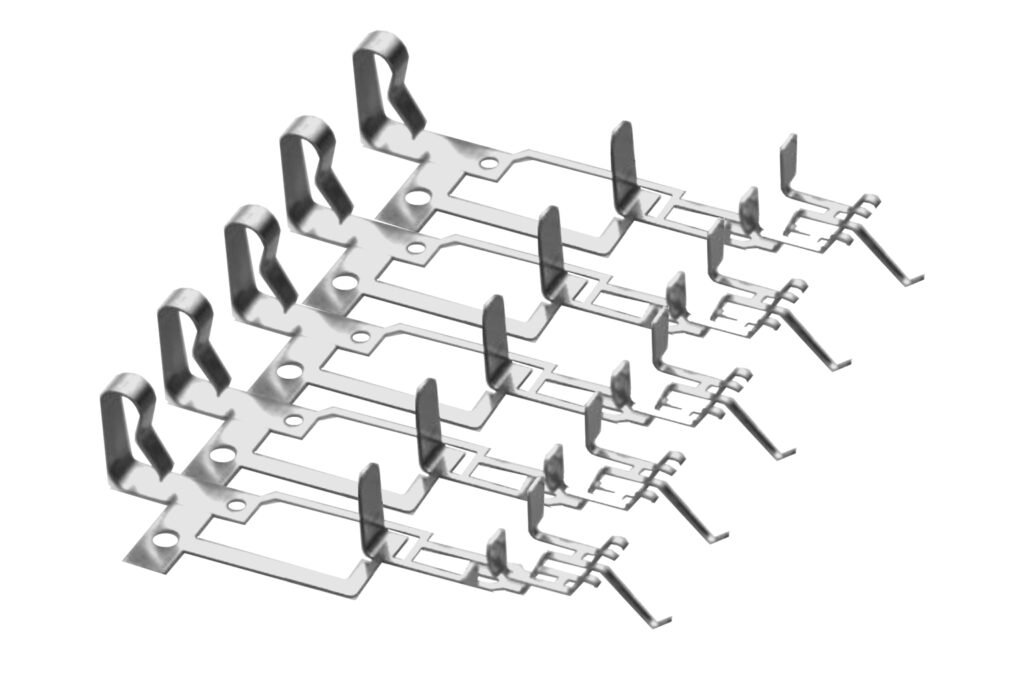

At Ditron, we specialize in stamping small, miniature, and micro-miniature components from thin-gauge ferrous and non-ferrous metals, including Beryllium Copper, Phosphor Bronze, and Stainless Steel. Our expertise spans both continuous-form and loose-part production, supporting high-performance applications in environments where precision and reliability are non-negotiable.

From the industry-changing Mosquito Clips to custom-stamped electrical contacts and terminals, our parts have helped shape the evolution of modern electronics through microscopic downsizing and high-speed, high-volume stamping excellence.

Explore Our Full Range of Materials

Sitemap | Privacy Policy | Cookie Policy | Terms of Service | Copyright © 2026. | All Rights Reserved