Crafting High-Quality, Tailored Metal Solutions with Unmatched Accuracy and Excellence

High-Speed Progressive Stamping

Unique size and tolerance capabilities.

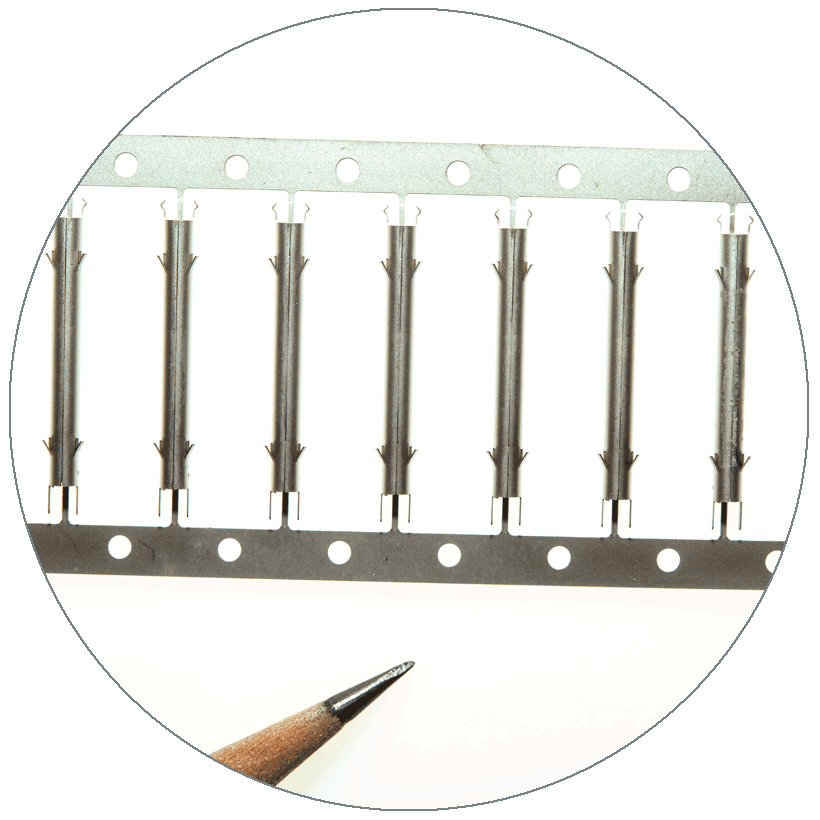

At Ditron, Inc., a PrecisionX Group company, we’ve set the standard in micro miniature stamping, delivering precision at scales few can achieve. Leveraging advanced progressive-die stamping technology, we specialize in pressure-forming nearly microscopic components at production speeds up to 1,600 strokes per minute.

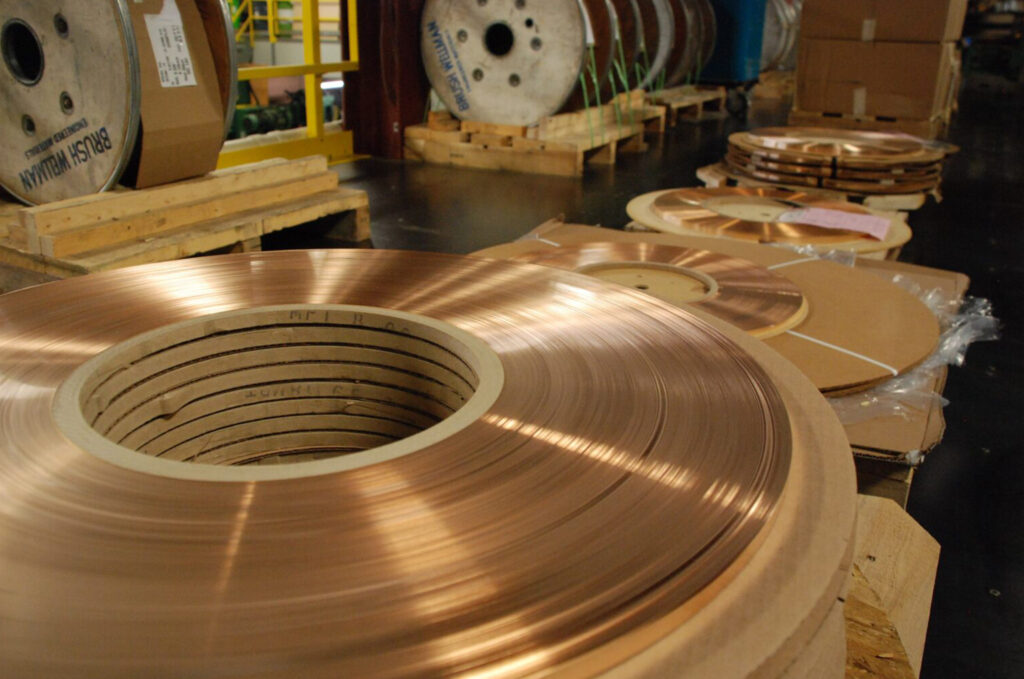

Our finely engineered dies enable burr-free stamping with sub-micron precision, consistently meeting tolerances as tight as ±0.0005”. This capability allows us to produce intricate parts from high-performance materials like Beryllium Copper, Phosphor Bronze, and Brass, delivering exceptional conductivity, strength, and durability.

From implantable medical devices to aerospace and defense electronics, Ditron’s micro stamping solutions are trusted in industries where precision, reliability, and consistency are non-negotiable.

Stamping miniature electrical connectors from Beryllium Copper (C172) and other conductive metals is part of our foundation. The name “Ditron” stems from “Dies for Electronics,” highlighting our deep roots in electronic part stamping.

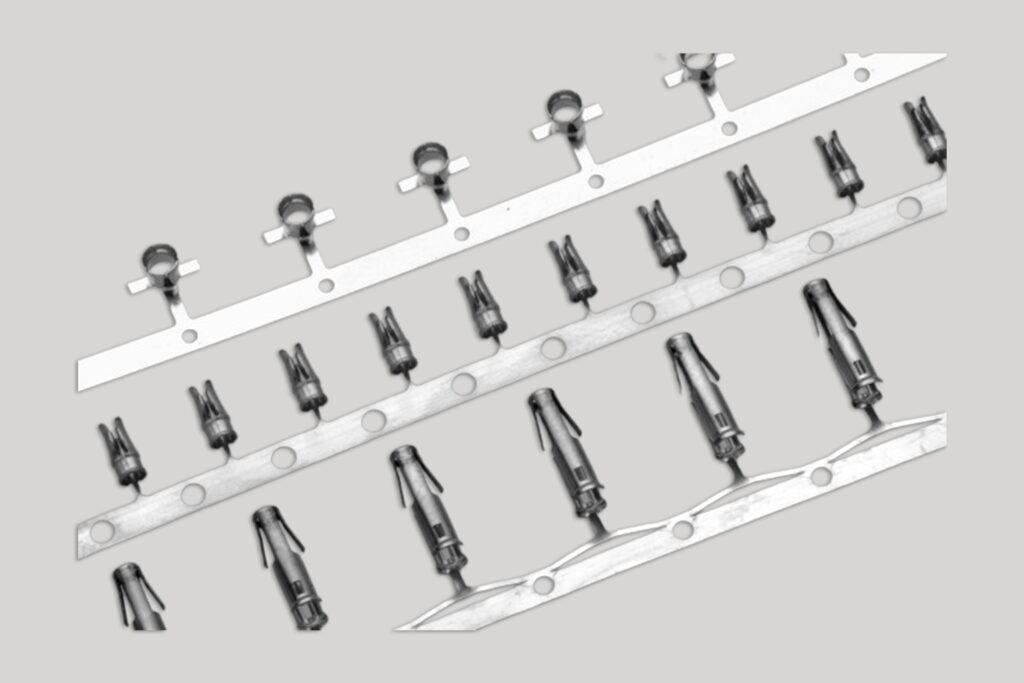

Our legacy began with the launch of our iconic Mosquito Clips—2-, 3-, 4-, and 6-finger micro connectors that helped transform modern electronics. Today, we continue to deliver high-precision, high-reliability stamped components for mission-critical electronic applications.

Progressive stamping is a fast, reliable, and cost-effective metal forming process ideal for producing small, high-precision components in large volumes. This advanced manufacturing method enables tight tolerances, repeatable quality, and efficient production speeds—making it a top choice for industries such as aerospace, medical devices, electronics, and automotive.

By combining multiple forming operations into a single die set, progressive stamping reduces material waste, eliminates secondary machining, and supports a variety of metals, including beryllium copper, stainless steel, and phosphor bronze.

Micro and miniature stamping is a specialized metal forming process used to produce ultra-small, high-precision components with tight tolerances and complex geometries. Ideal for industries such as medical devices, aerospace, electronics, and defense, this process supports the efficient production of intricate parts where accuracy and reliability are non-negotiable.

Utilizing advanced progressive-die technology, micro stamping enables high-volume manufacturing from performance-driven materials like beryllium copper, stainless steel, Kovar, and other specialty alloys.

Micro Stamping, Coining, Piercing, Slotting, Crimping, Tapping, Bending.

Also available through the PrecisionX Group platform, our Coining and Stamping solutions deliver exceptional precision and repeatability for complex metal components. With an advanced progressive coining process, we streamline production, reduce lead times, and lower manufacturing costs—while maintaining tight tolerances across every part.

We work with a broad range of materials including Kovar, Stainless Steel, Copper, and other specialty alloys. All coining tools are designed, built, and maintained in-house by our expert Tool and Die Makers, ensuring consistent quality, durability, and performance.

Progressive stamping ensures high repeatability, tight tolerances, and improved efficiency, resulting in shorter lead times and lower costs. All coining tools and dies are designed, built, and maintained in-house, supporting small to high volume projects with material thicknesses ranging from .003″ to .250″ and tolerances as tight as ±.0005″.

We manufacture precision parts from materials like Kovar, Stainless Steel, Copper, and more.

High-Speed Stamping offers exceptional speed and precision, with presses running at up to 1,600 strokes per minute (SPM) to maximize efficiency and throughput. This advanced capability enables us to handle high-volume production runs while maintaining the strict quality and accuracy required for critical components. Our process ensures that even at top speeds, every part is manufactured to exact specifications, minimizing waste and reducing lead times.

Single stroke stamping enables the production of complex parts with tight tolerances in a single operation, reducing the risk of material stress and defects. With its ability to maintain structural integrity while ensuring repeatability, single stroke stamping is ideal for producing high-quality components in industries where safety, durability, and performance are paramount.

Expertise Forming A

Wide range of material types

PrecisionX Group specializes in micro stamping, delivering high-precision components for industries such as aerospace, medical, and defense. Our expertise enables us to produce complex micro parts with exact tolerances, ensuring reliability and performance in critical applications. With advanced processes and the ability to work with a variety of materials, including Beryllium Copper, Kovar, and Inconel, we consistently meet the stringent demands of micro stamping for the most challenging environments.

PrecisionX Group specializes in forming difficult materials like Kovar, Inconel, and other nickel alloys, valued for their strength and resistance to high temperatures, oxidation, and chloride stress. Despite their challenging nature, our advanced techniques allow us to produce high-performance components with tight tolerances for critical applications in aerospace and electronics. We also ensure reliable metal-to-glass or ceramic seals, delivering durability and precision in the most demanding environments.

We specialize in stamping, deep drawing, and Swiss machining titanium for intricate medical devices and complex aerospace components, as well as other critical applications in satellite, space, and defense industries. Our expertise ensures high-precision components with tight tolerances, meeting the demanding standards of these sectors. With advanced technology and skilled craftsmanship, we deliver reliable, high-performance titanium solutions for complex applications.

Industries Served

Your partner in excellence.

Sitemap | Copyright © 2025. | All Rights Reserved