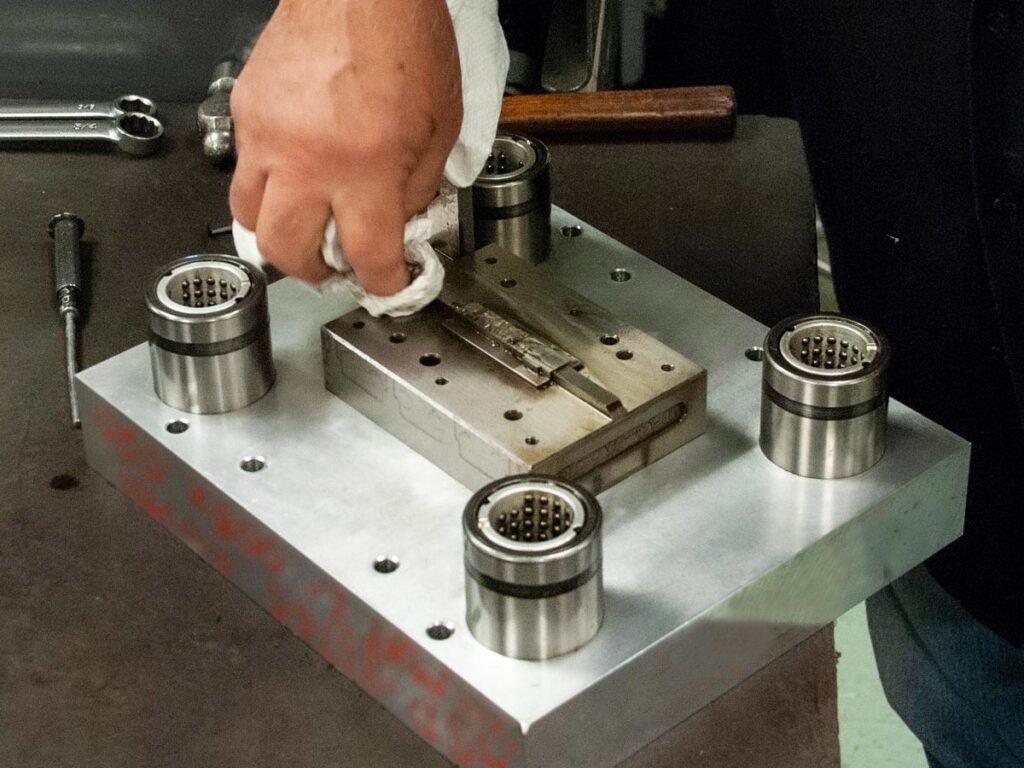

Precision Die Engineering for Complex Challenges

Engineering support for the efficient fabrication of Micro Precision Stamped parts is an integral part of Ditron’s total-solution approach. Our Engineers and diemakers are graduates of the most comprehensive apprenticeship program in the industry. They also receive ongoing training on stamping’s latest design trends, processes, press equipment, and materials. Continued education — combined with decades of seasoned metal-stamping experience — ensure your parts are always made using the best materials and most advanced processes.

Engineering positive outcomes through

a positive approach.

Success-driven “outside-the-box” thinking and engineering support is what Ditron is known for. Our Engineering and Tool Design Team approach every new project with a “can-do” attitude. One that focuses on “total engineering” solutions through continual assessment and improvement in every phase of the tool design.

Working closely with Quality Control, we inspect and refine each stage of development as needed to lessen production time, reduce waste, save cost, and ensure 100% spec-meeting consistency. Often, this can lead to innovation in tooling design, prototyping and testing, press set-up, finishing procedures, and even packaging techniques. At Ditron, we leave “no blank unpunched!”

We provide precision stamped part design engineering to help transform your concepts into manufacturable components. Whether you’re starting with a sketch, CAD file, or detailed spec, our team ensures your design is optimized for metal stamping production.

Using advanced 3D CAD tools and decades of expertise, we collaborate with your team to refine geometry, improve performance, and ensure efficient, cost-effective manufacturing. From prototyping to tooling, Ditron delivers engineered solutions that support high-speed production and high-reliability applications.

We combine decades of metal stamping expertise with advanced 3D CAD design to deliver high-performance progressive dies built for speed, accuracy, and durability. Early engineering involvement ensures your tolerance, function, and production needs are fully integrated into the tooling design.

Our engineers focus on repeatability, tight tolerances, and Six Sigma-level quality, while minimizing downtime and maintenance. Every tool is optimized for high-speed stamping, with real-time updates provided through detailed Gantt charts to keep your project on track.

We specialize in die engineering that supports high-speed, high-volume metal stamping with exceptional precision and reliability. Our team uses advanced 3D CAD tools and decades of experience to design progressive dies that meet tight tolerances and complex part requirements.

By integrating performance goals early in the process, our die engineering approach improves repeatability, reduces maintenance, and ensures Six Sigma-level quality. We provide detailed Gantt charts to keep your tooling project on schedule and aligned with production needs.

Industries Served

Your partner in excellence.

Sitemap | Copyright © 2025. | All Rights Reserved