Precision Deep Drawing for Complex Metal Components: Shaping Innovation, Delivering Reliability

Shallow and deep drawing with precise tolerances.

As a PrecisionX Group company, Ditron focuses on micro miniature and precision metal stamping, while offering customers access to a broader range of capabilities across the platform. Through PrecisionX Group, we provide custom deep draw manufacturing for OEMs that require complex, tight-tolerance metal components built for performance and reliability.

With advanced Deep Draw Transfer Press technology, PXG delivers high-precision deep drawn parts—from prototypes to full-scale production—ensuring accuracy, consistency, and cost efficiency. This collaborative platform allows Ditron customers to scale their product needs with deep drawing, progressive stamping, Swiss machining, and more—all under one trusted manufacturing partner.

Deep drawing complex shapes with sharp corners, precise radii, and tight tolerances for aerospace and defense applications. Working with materials like Kovar, Inconel, titanium and other hard-to-draw metals, we produce lightweight, durable housings and components built to perform in mission-critical environments.

With advanced deep draw metal forming capabilities, we manufacture complex, tight-tolerance components engineered to meet the rigorous demands of the medical device industry. From pacemaker enclosures and neurostimulator housings to surgical instruments and other implantable or life-saving devices, our deep drawing process ensures each part is produced with exceptional precision, consistency, and biocompatibility.

We specialize in deep drawn metal components for mission-critical applications across defense, aerospace, telecommunications, and industrial sectors. Our advanced deep draw process supports the production of complex geometries, including sonobuoys, battery enclosures, telecom housings, exhaust ducts, and heat sinks—all with tight tolerances, sharp corners, and precision forming.

With diameters from 0.020” to 18” and draw depths up to 18 inches, we manufacture high-performance deep drawn parts that meet the most demanding technical and environmental standards.

Max diameter to length ratio, minimum length to diameter ratio.

The PrecisionX Group of companies specializes in custom deep draw manufacturing for OEMs, delivering high-precision metal components designed to meet the most demanding applications. As a fully integrated platform, we leverage advanced multi-station transfer presses ranging from 5 to 300 tons, allowing us to produce complex geometries with unmatched accuracy and consistency. Our expertise spans diameters from .020” to 18” with draw depths up to 18”, ensuring versatility across Medical, Aerospace & Defense, Electronics, and Industrial applications.

At PrecisionX Group, we excel in deep drawing intricate shapes, maintaining tight tolerances and superior performance for mission-critical components. From prototyping to large-scale production, our cross-industry expertise, cutting-edge technology, and expanded capabilities make us the trusted partner for OEMs looking for exceptional quality and precision in deep draw manufacturing.

INCONEL®

KOVAR ®

MU-METAL®

HASTELLOY ®

STAINLESS STEEL

ALUMINUM

TITANIUM

COPPER

MONEL®

NICKEL

COLD ROLLED STEEL

BRASS

TANTULUM

BERYLLIUM COPPER

WASPALOY

HAYNES ® 282 ®

PHOSPHOR BRONZE

We excel in producing components with extremely tight tolerances across a wide range of sizes, ensuring precision and consistency in every part. Our capabilities allow us to handle both small, intricate components and larger, more complex pieces, all while maintaining the highest standards of accuracy. Whether working with fine details or larger dimensions, we deliver reliable, high-quality solutions tailored to meet the stringent demands of critical applications.

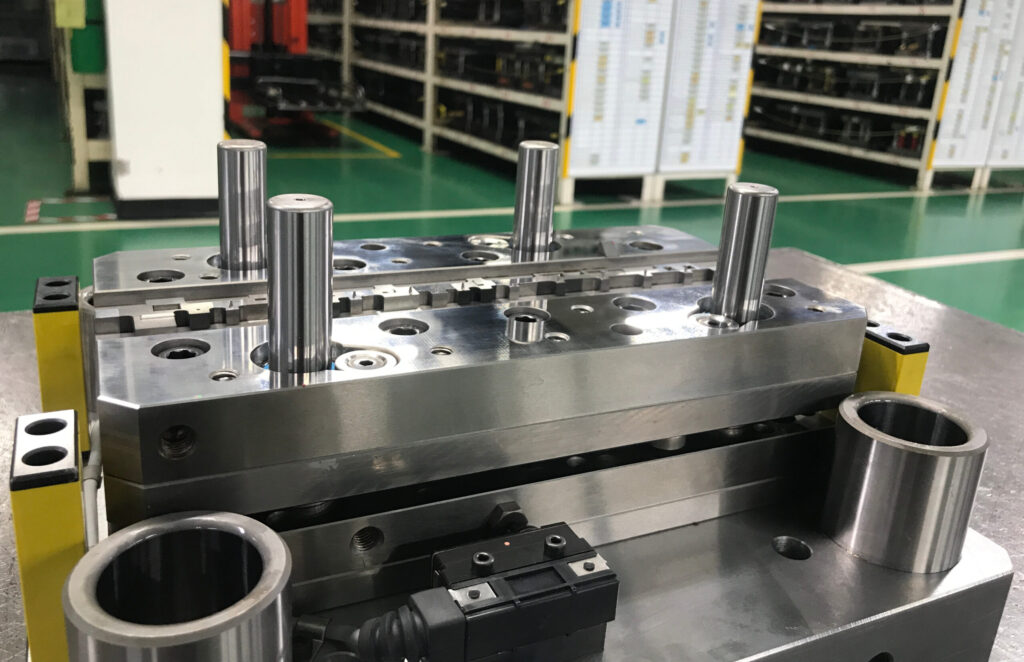

Our in-house Tooling and Die manufacturing department develops and manufactures all tooling and dies in-house, ensuring complete control over critical processes. This vertical integration allows us to optimize tool designs for efficiency, precision, and longevity, while maintaining the highest standards of quality and consistency. By managing the process in-house internally, we can rapidly iterate, refine, and tailor solutions to meet the unique needs of our customers.

Industries Served

Your partner in excellence.

Sitemap | Privacy Policy | Cookie Policy | Terms of Service | Copyright © 2025. | All Rights Reserved