PrecisionX is a company solely focused on satisfying the needs of OEMs and Tier 1 suppliers — from the design of parts and tooling, development and validation of the manufacturing process to mass production.

Shaping the World’s Most Demanding Components

Available through the PrecisionX Group platform, our integrated manufacturing capabilities are designed to meet the complex needs of OEMs and Tier 1 suppliers across aerospace, medical, defense, electronics, and industrial markets. We deliver end-to-end manufacturing solutions—from design and tooling to process development, prototyping, and high-volume production.

Our advanced production technologies include:

Deep Drawing

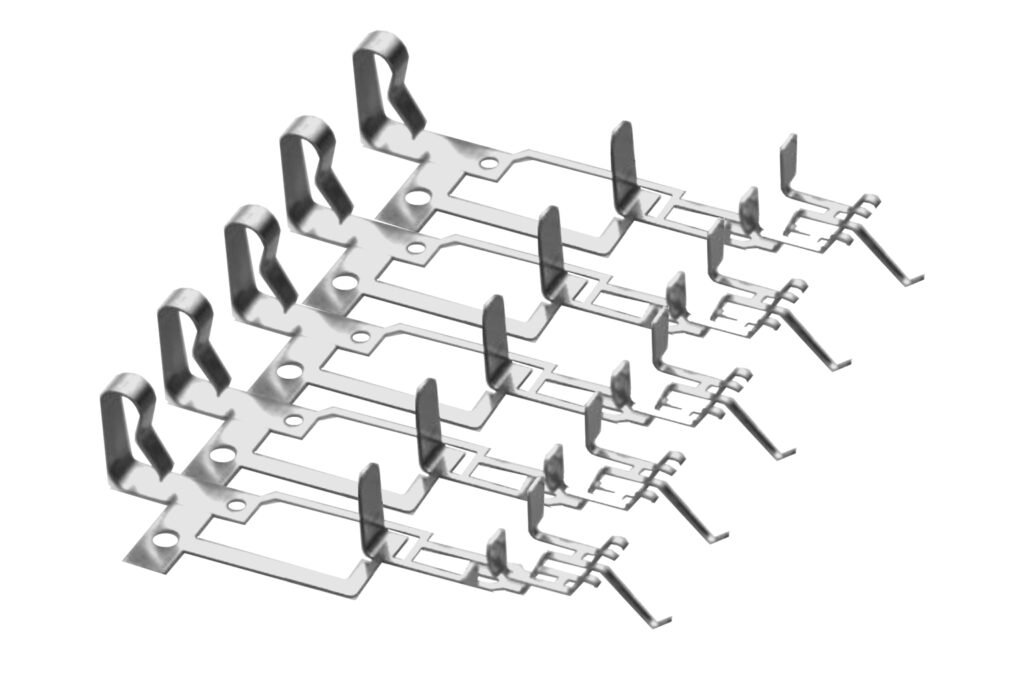

Progressive and Micro Stamping

Swiss Screw Machining

CNC Milling and Turning

Wire EDM Machining

With in-house tooling design and fabrication, we ensure rapid turnaround, precision, and process control. Our value-added services—such as heat treating, part assembly, finishing, and laser marking or printing—provide complete component manufacturing under one roof.

We specialize in forming and machining a wide range of metals, including:

Aluminum

Beryllium Copper

Stainless Steel

Titanium

Carbon Steel

High-performance nickel-based alloys like Inconel, Kovar, and Monel

Whether you’re producing tight-tolerance prototypes or managing full-scale production, PrecisionX Group delivers scalable, cost-efficient solutions that meet the most demanding industry standards.

Core Capabilities

Our deep draw expertise allows us to create complex, high-tolerance metal components from durable materials, ideal for industries requiring precision and strength, such as aerospace, medical, and defense.

We deliver high-volume, precision metal parts through progressive stamping, ensuring consistent quality for industries like aerospace, automotive, and medical, where efficiency and accuracy are critical.

Our micro stamping capabilities allow us to produce extremely small, intricate components with tight tolerances, perfect for medical devices and electronics that demand high precision.

We specialize in Swiss machining, crafting small, high-precision components with superior accuracy and surface finishes, ideal for complex parts used in medical, aerospace, and electronics applications.

Our CNC machining services offer the flexibility to create complex, precise components across various materials, ensuring exceptional accuracy for industries such as aerospace, defense, and medical.

We provide high-precision wire solutions for critical applications in medical devices, electronics, and telecommunications, ensuring durability, reliability, and top-tier performance.

Industries Served

Sitemap | Privacy Policy | Cookie Policy | Terms of Service | Copyright © 2026. | All Rights Reserved