Precision Engineering for Complex Components, Crafted with Accuracy and Innovation

Precision CNC Machining for Complex, High-Performance Components

Available through the PXG Platform: Advanced 5-Axis CNC Milling for Precision Components

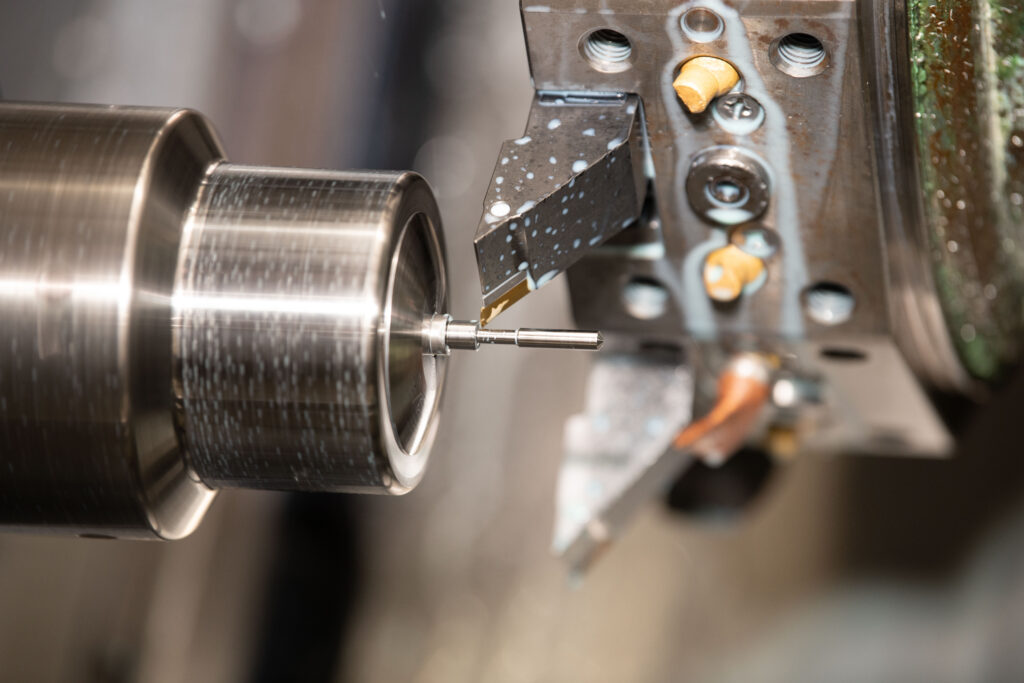

Through the PrecisionX Group platform, we offer advanced 5-axis vertical CNC milling for the production of custom precision components across demanding industries including aerospace, defense, telecommunications, semiconductors, and hermetic sealing. Our CNC milling systems accommodate parts up to 31.5” (L) x 17.7” (W) x 21.3” (H), delivering exceptional accuracy and consistency with tolerances as tight as ±0.0005”.

Our CNC machining capabilities include:

High-precision milling and drilling

Advanced operations like knurling, counterboring, and threading

Support for low- to high-volume production

Precision finishing of components post stamping or Swiss screw machining

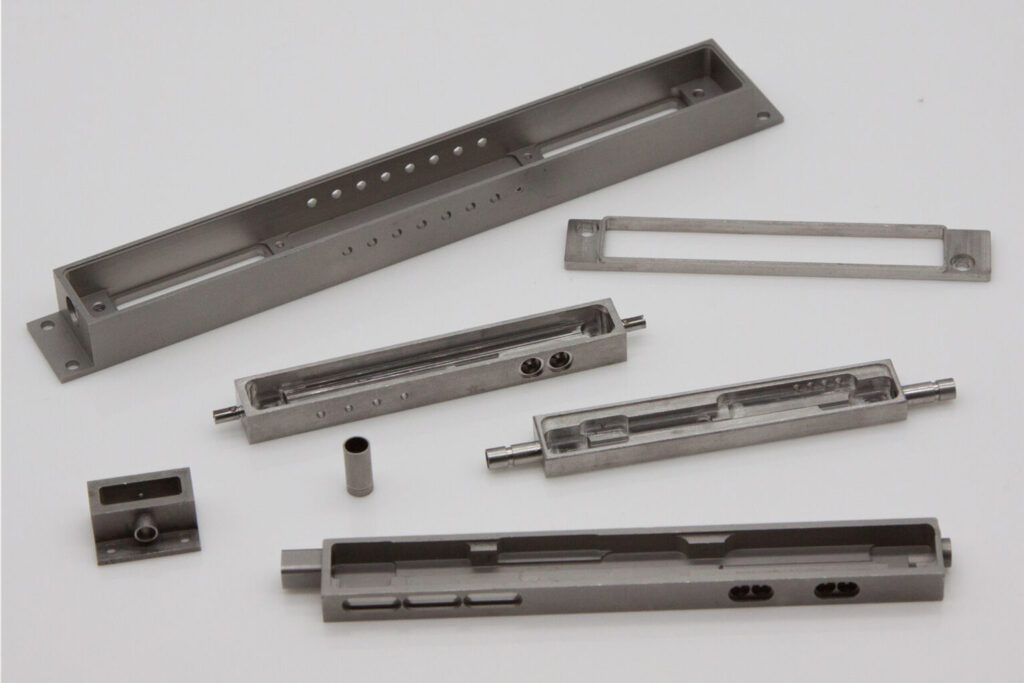

These capabilities allow us to machine complex geometries and multifaceted structures, meeting strict dimensional and lead time requirements—while maintaining cost-effective production. Typical parts include metal housings, sealed enclosures, and precision-machined packages for mission-critical applications.

Unique size and tolerance capabilities.

Our precision CNC machining capabilities at PrecisionX are tailored to deliver unique sizes and extremely tight tolerances for even the most demanding applications. With advanced machinery and skilled technicians, we achieve intricate details and precise dimensions that meet rigorous specifications. This capability allows us to handle complex geometries and customized sizes, ensuring that every component is produced with exacting accuracy. Our focus on precision and quality enables us to meet the high standards required across industries, providing reliable, high-performance parts for critical applications.

CNC MILLING CAPABILITIES

| 3-Axis with Trunnion | 5-Axis High-Precision | 3-Axis with Rotary | |

| 3 Axis Work Envelope (in) | 64″ x 32″ x 30″ (X, Y, Z) | N/A | 19.68″ x 15.74″ x 12.9″ (X, Y, Z) |

| Max Part Weight (lb.) | 2,000 | N/A | 660 |

| 5 Axis Work Envelope (in.) | 19″ x 18″ (Dia, Length) | 7.87″ x 6.2″ (Dia, Length) | 11″ x 14″ (Dia, Length) |

| Max Part Weight (lb.) | 200 | 33 | 220 |

| Spindle RPM (min-1) | 12,000 | 40,000 | 10,000 |

| Spindle Power (HP) | 30 (Cont.) | 10 (Cont.) | 15, 5 (Peak, Cont.) |

| Spindle Torque (ft-lb) | 22.4 (Cont.) | 1.3 (Cont.) | 39 (Peak) |

| Surface Finish Min (Ra) | 12 | <1 | 2 |

| Accuracy (in.) | 0.0001 | 0.00002 | 0.0002 |

| Repeatability (in.) | 0.0001 | 0.00002 | 0.000078 |

CNC TURNING CAPABILITIES

| Work Envelope (in.) | 14.17″ x 23.6″ (Dia, Length) |

| Main Spindle RPM (min-1) | 3,500 |

| Main Spindle Power (HP) | 30, 25 (Peak, Cont.) |

| Main Spindle Torque (ft-lb) | 369, 310 (Peak, Cont.) |

| Sub Spindle RPM (min-1) | 5,000 |

| Sub Spindle Power (HP) | 20, 15 (Peak, Cont.) |

| Sub Spindle Torque (ft-lb) | 92, 51 (Peak, Cont.) |

| Live Tool Spindle RPM (min-1) | 6,000 |

| Live Tool Spindle Power (HP) | 10, 5 (Peak, Cont.) |

| Live Tool Spindle Torque (ft-lb) | 30, 13 (Peak, Cont.) |

Industries Served

Sitemap | Privacy Policy | Cookie Policy | Terms of Service | Copyright © 2026. | All Rights Reserved